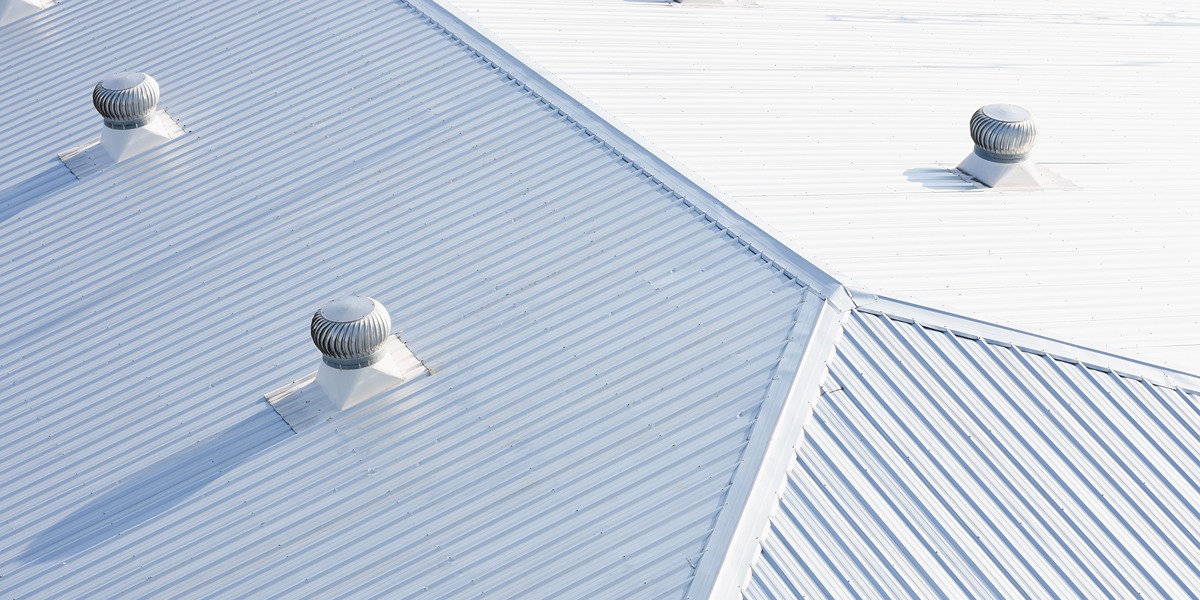

Standing Seam vs Exposed Fastener Metal Commercial Roofs

May 13th, 2023 | 6 min. read

If you've researched metal roofing options for your commercial building, you've probably learned there are two main types: standing seam and exposed fastener. But deciding which one to pick can be tricky. Choosing the right one for your building can be the difference between a great roof and a six-figure heap of scrap metal.

Fortunately, at GIDEON, we've installed every kind of metal commercial roof system, so we can help you make a suitable investment for your building. In this article, we'll discuss the pros and cons of each type of metal roofing so you can make the right choice and avoid hundreds of thousands of dollars in potential problems.

Table of Contents

- Types of Metal Roofs

- Exposed Fastener

- Corrugated

- R-Panel

- Polyisocyanurate (Poly-ISO)

- Spray Polyurethane Foam

Types of Metal Roofs

Exposed Fastener

The metal panels are fastened directly to the decking or framing with screws in an exposed-fastener roof. The panel edges are overlapped during installation, and screws go through both sheets. Exposed fastener roofs are also ribbed; rather than being flat, they are raised at regular intervals, creating a peak and trough. This substantially strengthens the panels.

There are three types of exposed-fastener metal roofs:

Corrugated

Corrugated exposed-fastener panels have rounded ribs, creating a wavy pattern. These are the classic metal panels you may have seen on old barns or other agricultural buildings. They typically come in widths of 37 ⅜", with ribs that are ⅞" high.

R-Panel

R-panels are a more modern exposed-fastener panel with straight and linear ribs rather than rounded ones. These panels are typically 36" wide, and the ribs are 1 ¼" high and 12" apart. This is by far the most common type of exposed fastener panel.

PBR-Panel

A PBR (purlin-bearing rib) panel is a type of r-panel that gets its name from its "purlin-bearing leg," an additional lip at the edge of the panel that increases the overlap between panels, making the roof more waterproof. These are a little more expensive than other R-panels or corrugated metal panels.

Pros

1. Less Expensive

Exposed fasteners roofs can be much less expensive than standing seam, as they typically use thinner metal, wider panels (fewer panels are needed), and require less installation skill.

2. Greater Supply of Qualified Contractors

Because exposed-fastener systems are less complex, there is a greater pool of contractors who can successfully install them. In fact, DIYers can often install exposed-fastener systems (something we do not recommend for standing seam systems).

More Traditional Look

Some people prefer the more traditional, rustic look with which exposed-fastener systems are associated.

Cons

1. Lots of Penetrations

Because you're drilling holes in the roof for all of those fasteners, you are creating many potential points for water penetration.

2. More Vulnerable to Expansion and Contraction

Because exposed-fastener systems lack the ability to move as freely as standing seam systems (the next type of metal roof we'll discuss), they are more susceptible to expansion and contraction, making them less practical in geographical areas with high-temperature variance.

3. More Maintenance Required

All of those additional fasteners are potential points of roof failure, which means you can expect more maintenance. It's not uncommon for fasteners to pop out of panels from expansion and contraction. Another common issue is gasket failure. The gasket is a piece of material (usually neoprene) that rests between the head of the fastener and the panel. The gasket will degrade over time with UV exposure, potentially creating an opening for water penetration.

To solve this issue, you can purchase special fasteners where the heads of the screws cover the gaskets and protect them from sun exposure. But these are about three times as expensive as standard fasteners.

4. Not Good for Low-Slope Roofs

For all the above reasons, exposed-fastener panels are not recommended for roofs with less than a 3/12 slope. On a slope any flatter than this, water doesn't shed well enough, and leaks become much more likely.

5. More Traditional Look

While the rustic look might be appropriate for barns or grain silos, it's probably not something you want on a more modern structure. The sleek, clean look of the standing seam roof would be a better choice in this case.

Standing Seam

As you might expect, one of the biggest problems with metal roofing is expansion and contraction, as metal is more affected by temperature fluctuations than other materials. Particularly in the summer, the cycle of daytime heat and nighttime cooling can result in a high degree of movement on a metal roof, and, over time, this can open up seams and pop screws out of panels.

In the 1960s, engineers devised an innovative solution to this problem: the standing seam metal roof.

In a standing seam roof, the metal roof panels are not screwed directly into the purlins (Purlins are part of the underlying building frame; they are beams that run horizontally along the length of the roof). Instead, each metal panel is bent at a 90-degree angle on one side, creating a 1-4 inch high "vertical seam" or "standing seam." Tough steel clips go over the standing seams, and these clips (not the metal panels) are then screwed into the purlins. In this way, no screws penetrate the panels along vertical seams; they are held in place by the clips alone. When the following panel is laid down, one of its standing seams goes over the clip. This hides the clip from view, contributing to the roof's aesthetic appeal, but, more importantly, covering and sealing the seam, which prevents water penetration.

This innovative solution accomplishes three things:

- The panels are secured to the building frame by the clips.

- When expansion and contraction occurs, the panels can slide side-to-side underneath the clips without damaging fasteners or popping seams open.

- The seams are hidden and sealed by the adjacent metal panel.

There are two types of standing seam metal roofs:

Snap-Lock

In a snap lock system, the clips and standing seams snap together when laid over one another. This system is effective for a roof that has an underlying layer of decking (usually made of plywood), but it is not appropriate for a commercial building without decking, where the panels are simply laid on top of the purlins. Wind entering the building in the latter system can break the snap-lock and destroy the system. For this kind of building, a mechanical lock is needed.

Mechanical Lock

In a mechanical locking system, the seams and clips snap in place and are then crimped tightly together, either with a handheld tool or a special seaming machine. This provides a tight seal that can easily resist even very powerful winds. However, it still allows each panel to move independently from one panel to the next, providing much-needed flexibility.

Pros

So how do standing seam systems compare to exposed fastener ones?

1. Less likely to leak

Standing seam commercial roofs are far less likely to leak than exposed fastener roofing because no screws are penetrating the panels along vertical seams, and these seams are covered and tightly sealed by the panels. The roof can also use longer panels than exposed fastener roofing, meaning there are fewer seams, which means fewer opportunities for water penetration.

For example, on a 20,000-square-foot exposed fastener roof, you'll have 16-20,000 screws penetrating the panels. On a standing seam roof of the same size, you'll have around 6,000 screws, which penetrate the panels along the eaves, rake edges, horizontal seams, and enclosures.

2. Can easily withstand expansion and contraction

When properly installed, the standing seam is a highly successful solution to the problem of expansion and contraction.

3. Requires less labor

A standing seam system also requires less labor to install because fewer fasteners are needed.

4. Longer service life

For all of the above reasons, a standing seam metal roof will last longer than an exposed fastener one and require less maintenance over its lifetime.

Cons

1. Harder to find qualified installers

Standing seam commercial roofs are more complex than exposed fastener systems; they require a high level of craftsmanship. For this reason, it may be difficult to find a competent installer, and you run a higher risk of getting poor workmanship.

2. More expensive

Due to their complexity and higher skill level required, standing seam systems are generally quite a bit more expensive than exposed fastener systems.

The Upshot

If you're a building owner or property manager, you know how tedious - and dangerous - it can be to make a major, complex purchase like a roof. Understanding the product is key to protecting your asset value. Now that you've learned more about commercial metal roofs, hop on a free call with GIDEON. Our nationally-recognized commercial roofing experts can help you understand your options so you can make the best decision for your building.

Schedule a Free Call

Hop on a call with a GIDEON expert and learn more about how GIDEON can help you with your commercial roofing project.

Eric Schlossenberg started roofing when he was 24 years old, when he went to work as a Conklin contractor. Over the course of his career, he’s installed hundreds of thousands of square feet of roofing systems, but he still has a special passion for where he started in roof foam and coatings, and is a founding member of The Roof Coaters Guild of America. Gregarious and outgoing, Eric brings a unique sense of fun to his work, whether he’s on a roof or in the office.